Billet Production

Aluminium Billet Production Facility

- 90.000mton annual production capacity

- 100% ultrasonic testing of aluminium billets

- 1050, 1070, 6060, 6061, 6063, 6082, 6463, 7005, 7020, 9003 alloys

- 6, 7, 8, 9, 10, 14 inch billet diameters

- Up to 7300mm billet length

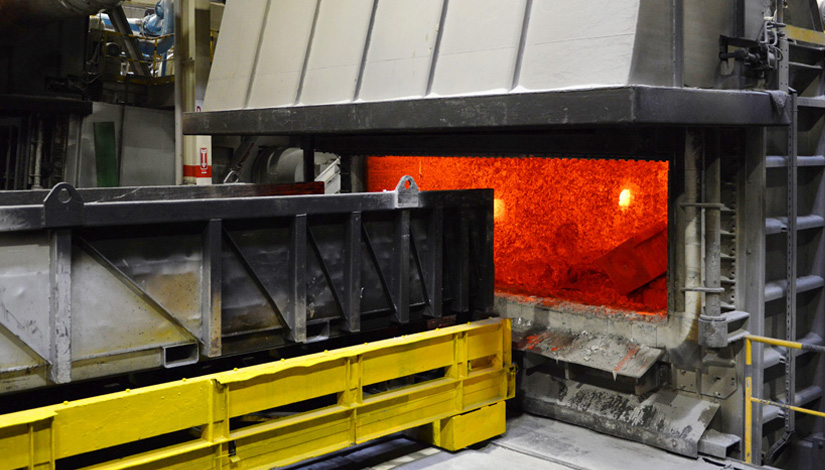

Billet Casting Line

The benefits of casting billets at the same facility is largely in the ability to customize a billet’s properties to better accommodate a particular profile specification. In addition, knowing that higher quality billets help to extend the life of an extrusion die and deliver improved yield and recovery rates, resulting in significantly lower costs, we made the strategic decision at our founding to control the quality of the billets we extrude.

Best in Its Class

Thanks to the ultrasonic test unit integrated into the production line, produced aluminum billets are fully controlled and transferred to the Extrusion Plant after ensuring that there are no central cracks or capillary voids.

The Asaş Billet Casting line uses a fully automated computer-aided, hot top air slip casting system to control the casting process and produce exceptionally superior quality aluminium billets that adhere to the highest European EN AW quality standards. This enhanced billet purity in turn yields stronger aluminium profiles, an essential outcome where the life time value of a product is concerned. We can also customize billet’s alloy limits according to a customer’s specific project and physical characteristic requirements.

The metallurgical results of uniform, continuously homogenized billets are considerably superior to those achieved by conventional batch system due to precisely controlled temperature cycles during heating, soaking and cooling.

Thanks to continuous billet homogenizing that each logs in the heating compartment uniformly heated to required temperature and logs then pass to the holding compartment where they are precisely kept at the required temperature throughout the holding time after entering the cooling station logs are subjected to intensive cooling that cooling speed is adjustable based on alloy.

Traceability

Each billet produced is registered with a lot number for traceability.